Are sustainability and attractive POP materials compatible?

At Pilotes, eco-design is a priority since 2013. We believe in creating environmentally friendly POS materials and retail furniture from the design phase. We achieve this by working with partners to minimize environmental impact, while still ensuring functionality and attractiveness.

Our approach covers all stages of the production chain:

STREAM UPWARD : We guide our partners to improve their processes and achieve higher standards in terms of environment, sustainability and quality.

INTERNAL : We continuously optimize our own methods to design ecological products, paying attention to material selection, design methods and quality standards.

STREAMWAY : Our POS and retail furniture is designed to have a minimal ecological footprint while meeting the needs of our customers.

OUR FOCAL POINTS

- Local production: We choose local partners to reduce transportation and support the local economy.

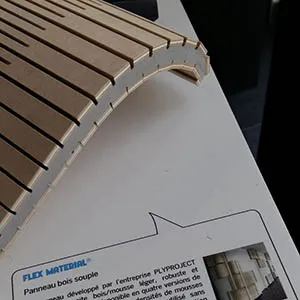

- Material optimization: We use the right amount of material or choose lighter materials adapted to their expected lifespan.

- Sustainable materials: We prefer recycled, recyclable or renewable materials. We base our choice on our material library, ranked according to environmental impact.

- Longevity: We design products that last longer or are adaptable to changing needs.

- Waste reduction: We reduce production waste and implement waste management systems.

- Logistics: We optimize logistics to reduce transportation.

- Energy efficiency: We design products with low energy consumption or integrate energy-efficient technologies.

- End-of-life: We design products that can be easily reused or recycled.

These criteria demonstrate our commitment to sustainability and our desire to work with partners and customers to create environmentally responsible projects.

Our tools

By using our tools, we help you to make informed decisions about your POP materials and reduce your environmental footprint:

ECO-PLV is our in-house life cycle assessment (LCA) tool, developed by our engineers

in 2013. Analyzing the environmental impact of your POP materials, it considers all stages of a

material's life, from production to disposal. ECO-PLV is certified by external specialists and

constantly being improved. Contact us to learn more about using ECO-PLV for your sustainable projects.

ECO-PLV is our in-house life cycle assessment (LCA) tool, developed by our engineers

in 2013. Analyzing the environmental impact of your POP materials, it considers all stages of a

material's life, from production to disposal. ECO-PLV is certified by external specialists and

constantly being improved. Contact us to learn more about using ECO-PLV for your sustainable projects.

SHOP!SKOR, the industry-standard LCA tool developed by our trade association SHOP!Association, uses scientific methods to assess the impacts of POP materials throughout their lifecycle. SHOP!SKOR takes into account 16 impact indicators, which are aggregated into a single score in micro points. SHOP!SKOR helps with:

- understanding the environmental impact of your POP materials.

- for redesign initiatives, choosing materials, finishes, packaging, and production processes that minimize environmental impact.

- communicating the environmental benefits of your POP materials and redesign initiatives to your team, suppliers, and customers.

The SHOP!ECO certification program is developed by retail experts and validated by the environmental

agency ADEME. It confirms a manufacturer's commitment to continuous improvement in eco-design practices.

Pilotes received this certification in 2015 and renews it every two years to ensure our ongoing

commitment to sustainability.

The SHOP!ECO certification program is developed by retail experts and validated by the environmental

agency ADEME. It confirms a manufacturer's commitment to continuous improvement in eco-design practices.

Pilotes received this certification in 2015 and renews it every two years to ensure our ongoing

commitment to sustainability.